Product Overview

The Bambu Lab P1S is a high-speed, enclosed 3D printer designed to deliver professional-grade performance with minimal effort. Equipped with the AMS 2 Pro(Automatic Material System), it supports multi-material and multi-color printing with seamless filament management. The P1S combines precision, reliability, and intelligent automation in a robust enclosure that ensures optimal print quality across a wide range of materials. Perfect for both professionals and enthusiasts, it offers a powerful, ready-to-print solution right out of the box.

|

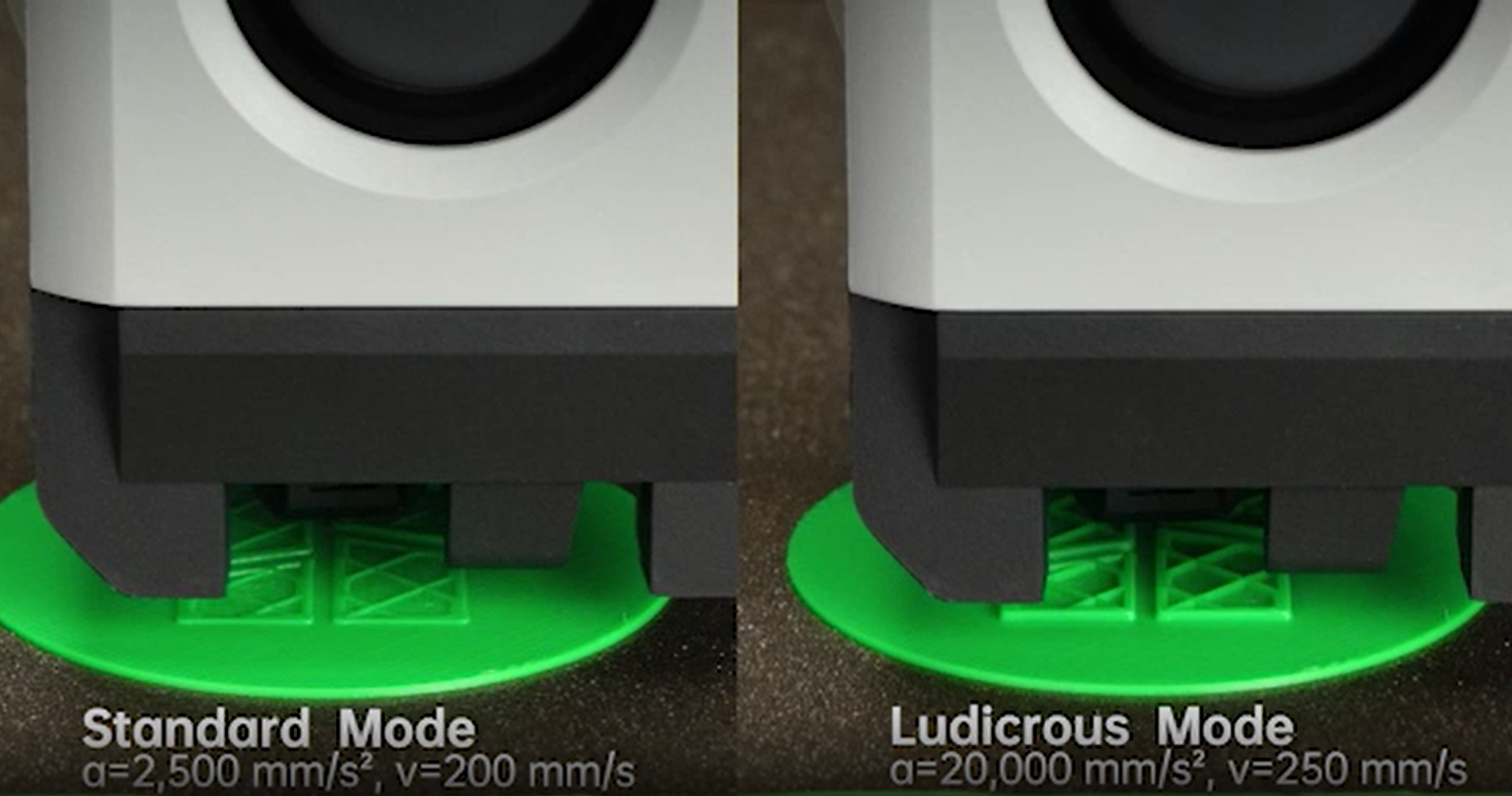

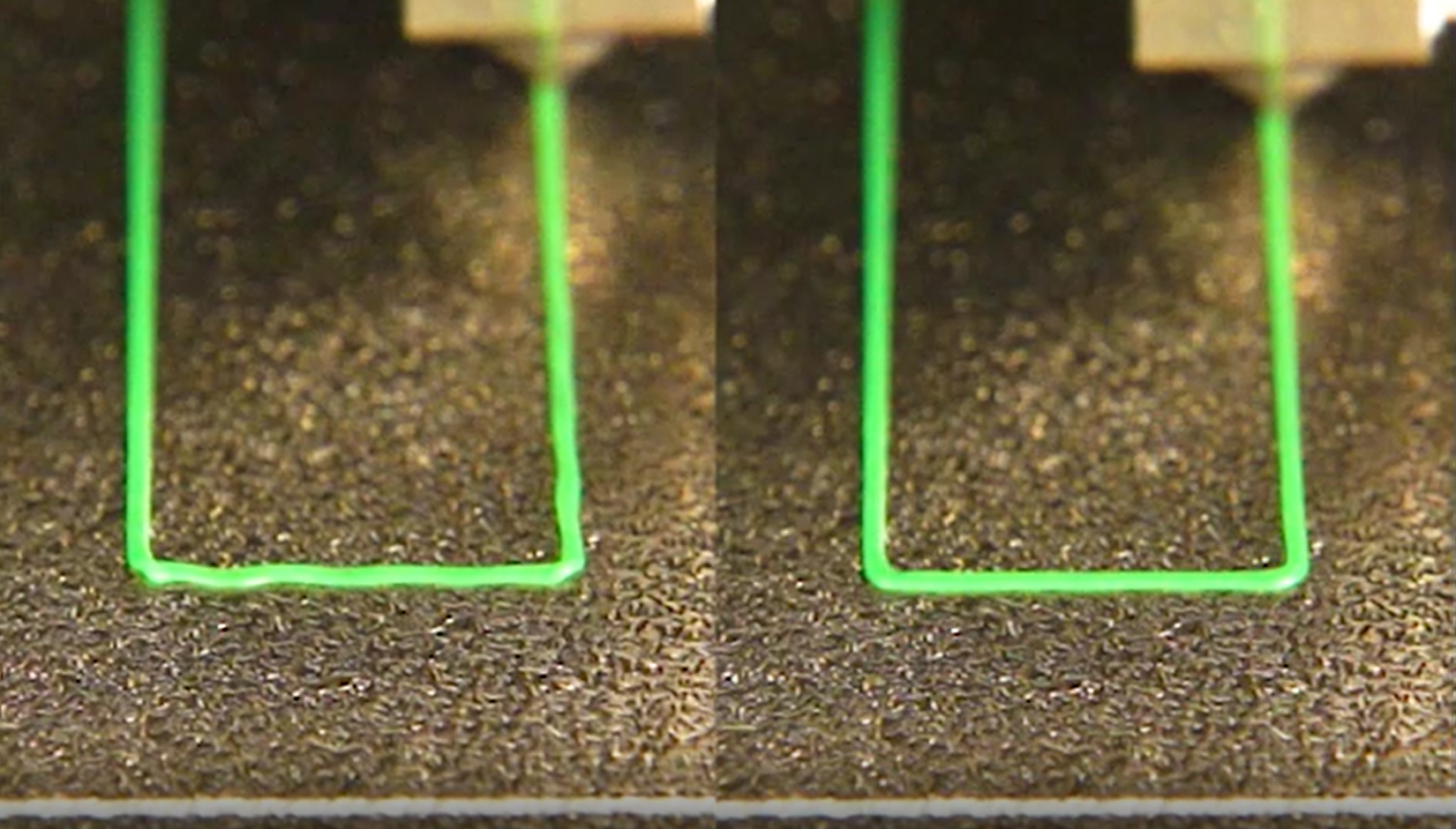

CoreXY up to 20000 mm/s² Acceleration

The P1 series inherits the proven kinematics and motion control system of the Bambu Lab Flagship printer. It prints with a top speed of 500 mm/s, the acceleration from zero to 500 mm/s takes just 0.025 seconds.

|

Multi-color capabilityGet the AMS combo to unleash Multi-color printing capability. (up to 16-color if you stack up 4 AMS units). Purchase additional AMS units for more colors. |

|

|

Vibration Compensation & Pressure Advance The active vibration compensation (XY) algorithm and pressure advance guarantees extra smoothness and gets you good prints.

|

Fully loaded with advanced features |

|

|

|

Advanced Technologies |

|

|

All-metal Hotend

Durable material made to support long-time 3D printing filaments including ABS, carbon fiber at high temperatures. It provides accurate and smooth extrusion to achieve quality printing performance.

|

Filament Run-out Sensor

Eliminate the problem of empty spools during printing. Change filament when empty and Resume.

|

|

Power Loss Recovery

Worry-free from a power cut-off, you can resume the print from where it left off

|

Semi-automatic Belt Tensioning

The tension of the belt is essential for ensuring dimensional accuracy. Resonance frequency identification runs every time to help maintain the correct tension.

|

|

Fans with Speed Feedback

The speed feedback sensor monitors the fan's speed ensuring that the fan is able to operate at its optimal speed at all times.

|

Liveview &Time-lapse

The built-in chamber camera enables easy print monitoring on Bambu Studio and Handy, and timelapse video creation.

|

Specifications

| P1S | |

| Build Volume(WxDxH) | 256 x 256 x 256 mm³* |

| Shell | Enclosed (Plastic & Glass) |

| Hot End | All-Metal |

| Nozzle | 0.4 mm Stainless Steel Included |

| Max Hot End Temperature | 300 ℃ |

| Nozzle Diameter |

0.4 mm (Included) 0.2 mm, 0.6 mm, 0.8 mm (Optional) |

| Build Plate Surface Compatibility |

Bambu Textured PEI Plate, Bambu Cool Plate, Bambu Engineering Plate, Bambu High Temperature Plate |

| Max Build Plate Temperature | 100℃ |

| Max Speed of Tool Head | 500 mm/s |

| Max Acceleration of Tool Head | 20 m/s² |

| Control Board Fan | Closed Loop Control |

| Chamber Temperature Regulator Fan | Closed Loop Control |

| Auxiliary Part Cooling Fan | Closed Loop Control |

| Air Filter | Activated Carbon Filter |

| Supported Filament |

Ideal: PLA, PETG, TPU, PVA, PET, ABS, ASA Capable: PA, PC |

| Chamber Monitoring Camera |

Low Rate Camera 1280 x 720/0.5fps Timelapse Supported |

| Filament Run Out Sensor | Yes |

| Physical Dimensions |

P1S:389 * 389 * 458 mm³, Package size 485 × 480 × 530 mm³, Net weight 12.95kg, Gross weight 17.60 kg P1S Combo:Package size 485 × 480 × 585 mm³, Gross weight (AMS included) 21.60 kg |

| Electrical Requirements | 100-240 VAC, 50/60 Hz, 1000 W @220 V, 350W@110V |