Product Overview

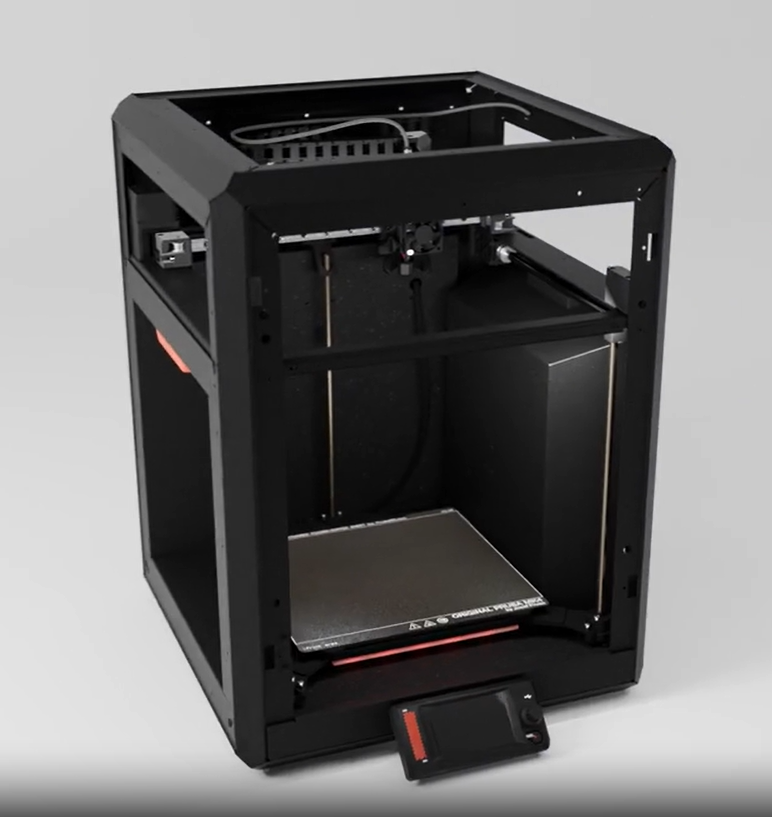

This is the versatile 3D printer for every kind of project. Thanks to the print volume of 300×300×330mm, an actively heated chamber up to 60°C, and the new AC convection heatbed, it is perfect for effortless, warp-free printing of demanding materials. It’s the best tool for every kind of business, home workshop, shared makerspaces, or design studios - all in one package. You can integrate it into our open ecosystem while remaining completely free from the limitations of a walled garden. Print in top quality with any material, use any slicer, and run the printer completely offline if you choose.

The exoskeleton frame and smart design choices ensure maximum firmness and robustness, which translates directly into outstanding print quality. With intuitive software and one-click printing, users can begin printing their first model within minutes after unpacking. Plus, access to over one million free 3D models on Printables.com guarantees a constant supply of exciting projects. You will always have something to print!

CORE One - Doubled!

Huge print volume, active heat circulation, and more!

The CORE One L is much more than just a larger CORE One. We didn't just scale it up; we took everything that worked great and added features for effortless large-format printing.

For the body, we have chosen an effective combination of a solid steel frame and aluminum panels to create a lightened version of our proven exoskeleton design. And the results are compelling: the machine’s outside dimensions are only 10% larger than the CORE One, yet it maintains the same weight, and the print volume is doubled!

The standard heatbed has been replaced with our new AC convection heatbed with active air circulation for flawless heat distribution in the chamber. The printer comes with a detachable 1080p camera with night vision, two nozzles in the package, fully automatic chamber temperature management, easier FLEX filament feeding, and much more.

This machine covers everything: from ambitious hobby projects to highly demanding manufacturing!

Think Big. Print Big.

Because now everything fits!

The 300×300×330 mm print volume (CORE One’s volume doubled) is the sweet spot for any kind of project. It lets you print large functional parts, production fixtures, architectural models, full-size cosplay helmets, and other massive objects all in one piece. And the best part? The new heatbed has the best heat distribution possible thanks to the materials used, so you can effortlessly print from edge to edge.

New AC Heatbed with Convection Heating

No cold corners, fast heat up

The new massive AC heatbed is made of a thick block of aluminum for the best possible heat distribution. This results in perfectly uniform heat distribution from edge to edge - no cold spots, no cold corners. You can place your model anywhere in the print area without worrying about lifted corners or warping. Two fans on the underside of the heatbed create a convection effect - they bring cold air in and blast it across the massive heated surface to quickly bring the chamber all the way up to 60 °C.

Flawless Precision

What You Design is What You Get

You can be sure that with our internally developed, quality-focused print profiles, your models will turn out exactly how they were designed, with perfect dimensional accuracy as proven by CT scans. CORE One L utilizes the proven Nextruder with 360° cooling for flawless printing of 75° overhangs, saving both time and material.

Maximum Speed without a Catch

Fast with every filament, not just specialized ones

Don’t limit your projects to a small selection of specialized “high-speed” filaments. Use any PLA, PETG, or many advanced materials. The CORE One series represents our fastest printers yet: robust CoreXY kinematics, high-flow nozzle, Input Shaper, factory-tuned print profiles for 200+ filaments - it’s all there. However, we never sacrifice print quality to chase speed records. The prints are always solid, durable, and won’t crumble in your hand.

Robust Steel Exoskeleton

A design that works and looks the Part

Prusa CORE One is built as an all-steel exoskeleton. The enclosure is an integral part of the printer, providing it with outstanding stability and rigidity. However, maintenance is still simple, and if you need to replace a worn part in a couple of years, it’s a complete no-brainer. You can take everything apart with a screwdriver. As usual with us, we hold parts in stock for years

|

|

Create colorful 3D objects!Ready for the MMU3* |

|

| The CORE One L is compatible with the MMU3, the add-on for the fastest single-nozzle printing with up to five filaments at the same time. You can create beautiful, colorful objects, and you won’t have to throw half of your filaments away or constantly clean the surroundings of your printer. Our solution uses an innovative retraction technique and a compact wipe tower to manage filament changes. This not only reduces the wasted filament but also deposits all the waste to a single, tidy block. *In upcoming MMU upgrade. | |

|

|

|

|

Make it your own!Designed for modders |

|||

|

No parts of the printer are glued together, everything can be taken apart with a set of screwdrivers and there’s plenty of room for mods, creativity and customization – so go ahead and make the CORE One L your own! Print magnetic holders, organizers, or just plain fun stuff to make your printer stand out. Our software and firmware are open-source and you can grab the source codes at GitHub.com. This allows you to modify the code, come up with your own improvements and tweaks. We often cooperate with our community members on new features, and you can become one of them! Or if you don’t want to dig into the code, you can try your hand at modifying the printed parts of the printer. There are dozens of opportunities for all sorts of projects! |

|||

|

|

|

|

Technical Parameters

| Measurements | |

|---|---|

| Build Volume | 300 x 300 x 330 mm | 11.8 x 11.8 x 12.99 in |

| Filament diameter | 1.75 mm |

| Layer height | 0.05-0.30 mm |

| Printer dimensions | 21,9 kg, 469×521×635 mm; 18.5×20.5×25 in (W×D×H) |

| Electronics | |

| Mainboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper Drivers | Trinamic 2130 |

| Stepper motors | 1.8° Stepper motors |

| Extruder | |

| Extruder | Nextruder, Direct Drive, E3D V6 compatible (with adapter) |

| Extruder electronics | Custom breakout board for connecting fans, thermistors and other parts. |

| Filament path | Aluminum heatsink, all-metal hotend |

| Drive system | Nextruder Planetary Gear System, 10:1 gearbox ratio |

| Cooling fan | High-performance turbine, 360° cooling system |

| Nozzle | High-flow Prusa Nozzle brass CHT - 0.4 mm + Abrasive-Resistant 0.4mm nozzle in the box |

| Max. operating temperature | |

| Max nozzle temperature | 290 °C / 554 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Max chamber temperature | 60 °C / 140 °F |

| Controls | |

| LCD screen | 3.5″ graphic 65k color screen |

| Touch control | Yes |

| Firmware update interface | USB drive, Prusa Connect, Prusa Mobile App |

| Prusa Connect support | Yes |

| Prusa App for iOS and Android support | Yes |

| Quick-Swap nozzle system | Yes |

| Lighting | Yes |

| Accessories | |

| Internal camera | Included in the box, installation optional |

| MMU3 support | Yes. MMU3 (available Jan 2026) |

| Advanced Filtration System | optional addon |

| GPIO Board compatibility | Yes |

| Accelerometer compatibility | Yes, built-in |

| Connectivity | |

| Ethernet connection | Yes |

| Other connectivity | NFC receiver |

| Sensors | |

| Filament Sensor | Yes (2 sensors) |

| Loadcell sensor | Yes |

| Thermistors | 5 high-precision thermistors (genuine Semitec) |

| Fan motors monitoring | Yes |

| Door sensor | Yes |

| Printing | |

| Print medium | USB drive / LAN / internet via Prusa Connect or mobile Prusa App |

| Print surface | Magnetic heatbed with removable PEI spring steel sheets |

| First layer calibration | Fully automatic (thanks to the Load Cell sensor) |

| Bed calibration | Automatic, Mesh Bed Leveling (only on print area) |

| Input shaper | Yes |

| Supported materials | PLA, PETG, Flex, PVA, PC, PP, CPE, PVB and when using the optional Advanced Filtration System ABS, ASA, HIPS, PA |

| Phase Stepping | Yes |